I owned a construction company for 40 years, and one Friday a driver left a bag of cement on the back of a pickup truck.

It rained Saturday and Sunday, and someone from the New Jersey Department of Environmental Protection (DEP), on her very first day of work, drove by our facility, and she saw a little trail of cement going to within two inches of a catch basin.

She gave me a warning and informed me that I could have gotten a $27,000 fine. So we looked into solving that problem, and we came up with an idea that had started in California. We imported it and began doing business in New York, New Jersey and Pennsylvania.

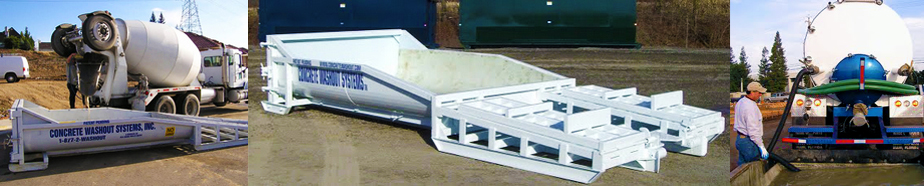

Concrete Washout Systems (CWS) is a portable, self-contained and watertight roll-off bin that controls, captures and contains concrete washout and runoff. It makes it easy to wash out concrete trucks, pumps and equipment on-site, facilitating easy off-site recycling of the same concrete materials and wastewater.

Capturing and recycling washout just isn’t a ’green’ thing to do, it’s a legal requirement, and builders ignore that at their own peril. The fines are pretty steep. If you washing out a concrete truck along a curb for five days, all of sudden you are in for $30,000. It also varies depending on the agency handing out the fine. For instance, with the federal Clean Water Act, it could be as much as $15,000 a day.

Dumping concrete washout, or handling it inefficiently can be costly in terms of fines, but it’s also damaging to the environment. The material inherently has a high PH, a measure of how acidic or alkaline a substance is, a value of 12, and contains a range of corrosive chemicals. It’s like pouring ammonia, oven cleaner or a liquid drain clearing product directly into the ground.

The pH scale goes from 0 to 14, where 7 is neutral. A change in one pH unit means a tenfold change in concentration, similar to the Richter scale and measuring earthquakes. High pH levels are damaging to fish and vegetation, with effects including inhibited growth, damage to soil and plants and substantial alteration of the soil and plant chemical composition even after the pollution source is gone.

CWS takes the material to its treatment plant, reducing it to a pH value of seven. The heavy metals and solids are removed, and it becomes clean, reusable water that is delivered to the Passaic Valley Sewage Commission.

Despite the sanctions that can be applied for not handling concrete washout responsibly, and the environmental damage that can be done from letting it spill, some builders still try to cut corners, hoping they can get away with it. Many still do.

One of the benefits of using CWS is obviously, that you will comply with the law. The second benefit is that a lot of people use homemade contraptions, or maybe just dump the stuff on the ground, and they hope they don’t get caught. We recycle everything we take … no waste at all going to a landfill.

Trained drivers deliver the washout containers to a building site. When the containers are full, the drivers remove and replace them as required. Unfortunately our biggest competition still comes from people just dumping this caustic material on the ground. Much of it comes down to a lack of enforcement.

A lot of people just don’t know the laws exist … or they just don’t realize they are polluting their own ground. It’s kind of ironic that the state of New Jersey is really big on cleaning up brownfield lands, spending tens of millions of dollar to clean up an industrial site. And a new building will go up, and chemicals like cadmium and lead will get dumped all over the property.

We are strong supporters of public advocacy groups and events helping to educate the public about the need to be environmentally aware. That knowledge can lead to people who witness concrete washout being dumped, calling their municipalities and building inspectors. These organizations play a major role in making citizen’s more aware of the importance of clean water and how they can directly help in these efforts. The less we pollute, the better it is for everybody.

By Roger Haftek, President